Product Support and FAQs

We want to make sure you can get your job done right, so we have created instructional guides and videos to help guide you through common safety and product maintenance issues. See the list of topics below.

Browse by Product

Battery

Oregon 40V battery technology is paving the way for greater productivity and efficiency from home projects to commercial jobs. Get expert tips on interchangeably using these batteries between products, troubleshooting tool-to-battery communication, and tips for getting the optimal life out of your battery.

Brush Cutter & String Trimmer

With our step-by-step demonstrations and simple maintenance tips, learn expert techniques for managing, using, and loading a variety of trimmer heads and trimmer line.

Chain Saw

Keep your chainsaw working as hard as you do. From sharpening to part replacement, our experts have curated chainsaw repair and servicing demos, along with time-saving tricks, to keep your tools running at top performance.

Edger

With proper tool maintenance and expert tips for how to edge a lawn, you can help take your property to the next level. Check out our edger maintenance tips, how-to’s, and more.

Grinders and Sharpeners

Proper installation and maintenance of your Oregon Chain and Mower Blade Grinders and Sharpeners is crucial for maintaining optimal performance of your tools. Learn how to correctly set-up, operate, and maintain your grinders and sharpeners.

Harvester

For maximum productivity, get advice, tips, and best practices to keep the cutting system on your harvester machine in top condition.

Hedge Trimmer

Neglecting blade maintenance and damage can lead to poor, or no, equipment performance. Help extend the health and longevity of your hedges with tactical hedge trimming tips and quick service “how-to” resources.

Lawn Mower

Proactively service your mower to ensure optimum performance year after year. Check out some of our tried-and-true techniques to get your mower blades aggressively sharp, troubleshoot repairs, and master lawn mower tips for a healthier looking lawn.

Leaf Blower

Take a dive into our support resources to discover the many leaf blower uses and tips to keeping it running at maximum performance all year.

Log Splitter

Check out the log splitter manual and our curated expert advice for maximizing productivity and lowering wood-waste with less effort and fewer maintenance demands.

Pole Saw

A properly maintained pole saw is safer and easier to operate. Check out our support resources full of helpful product information and tips to use for any job – any time.

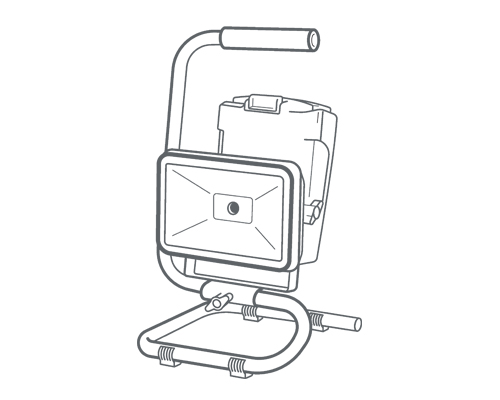

Other

With easy-to-follow installation instructions and time-saving maintenance tips, learn expert techniques for assembling, operating, and maintaining your other Oregon products.