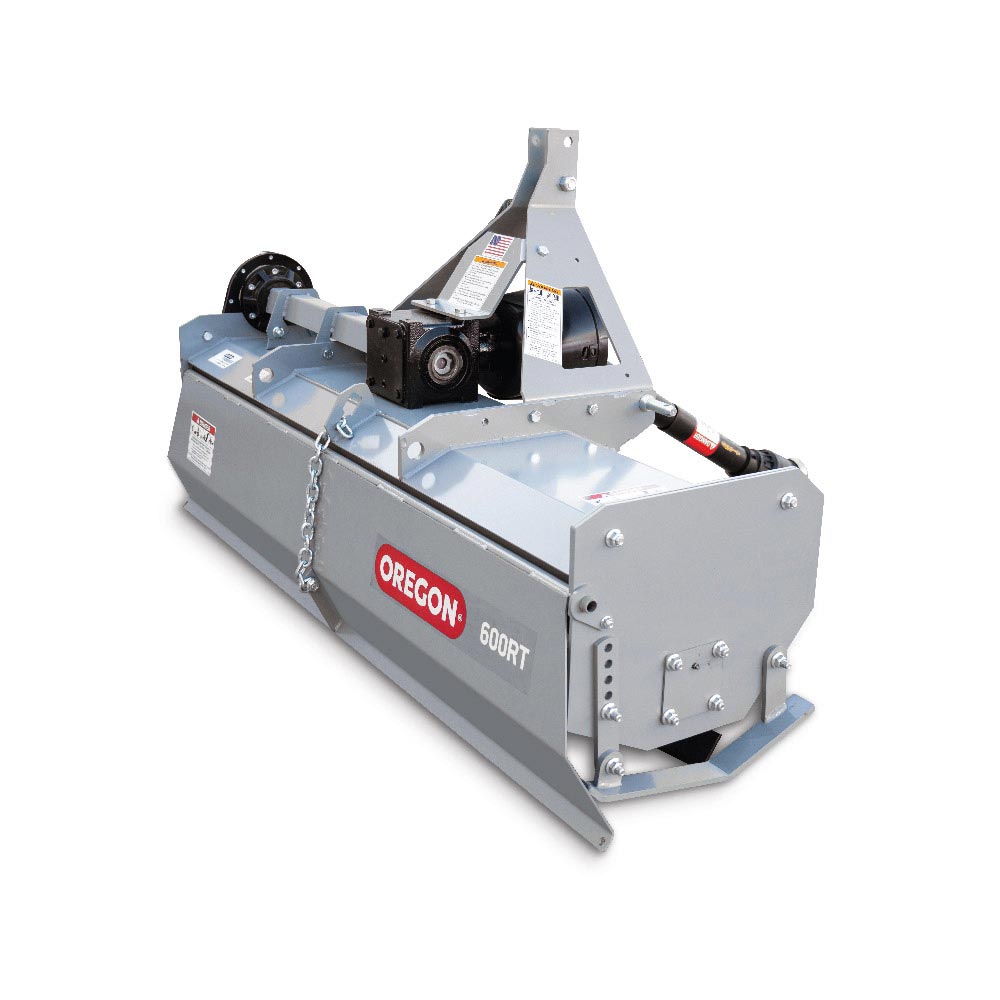

Rotary Tiller, 60"

Model OR60RT-1

Available at limited Tractor Supply Co stores in North Dakota, South Dakota, Michigan, Minnesota, Wisconsin

Find A Store

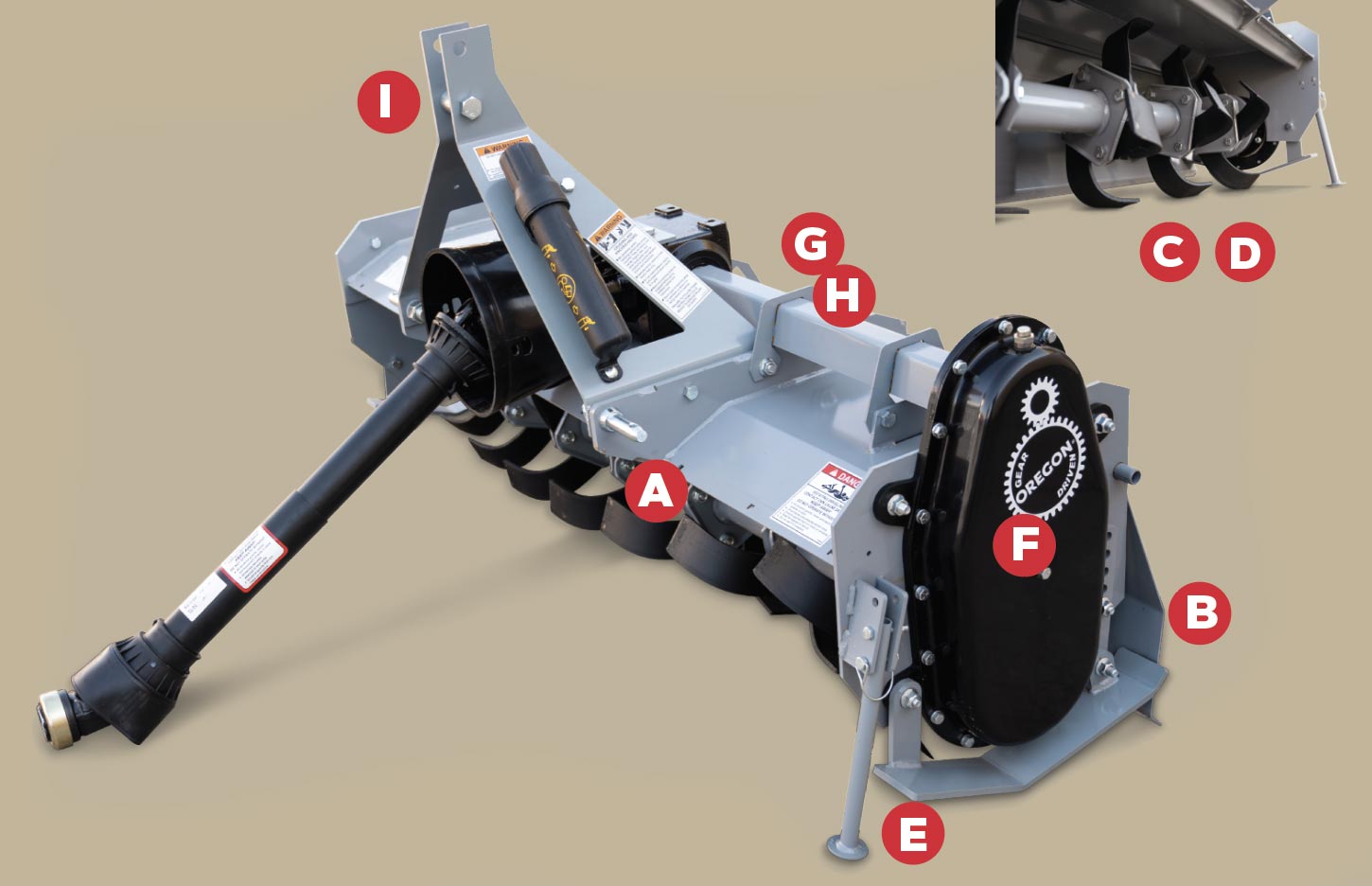

- Conquer wet, rocky, and sandy soil in preparation for sowing seeds, planting trees, or landscaping with Oregon’s 60" Rotary Tiller.

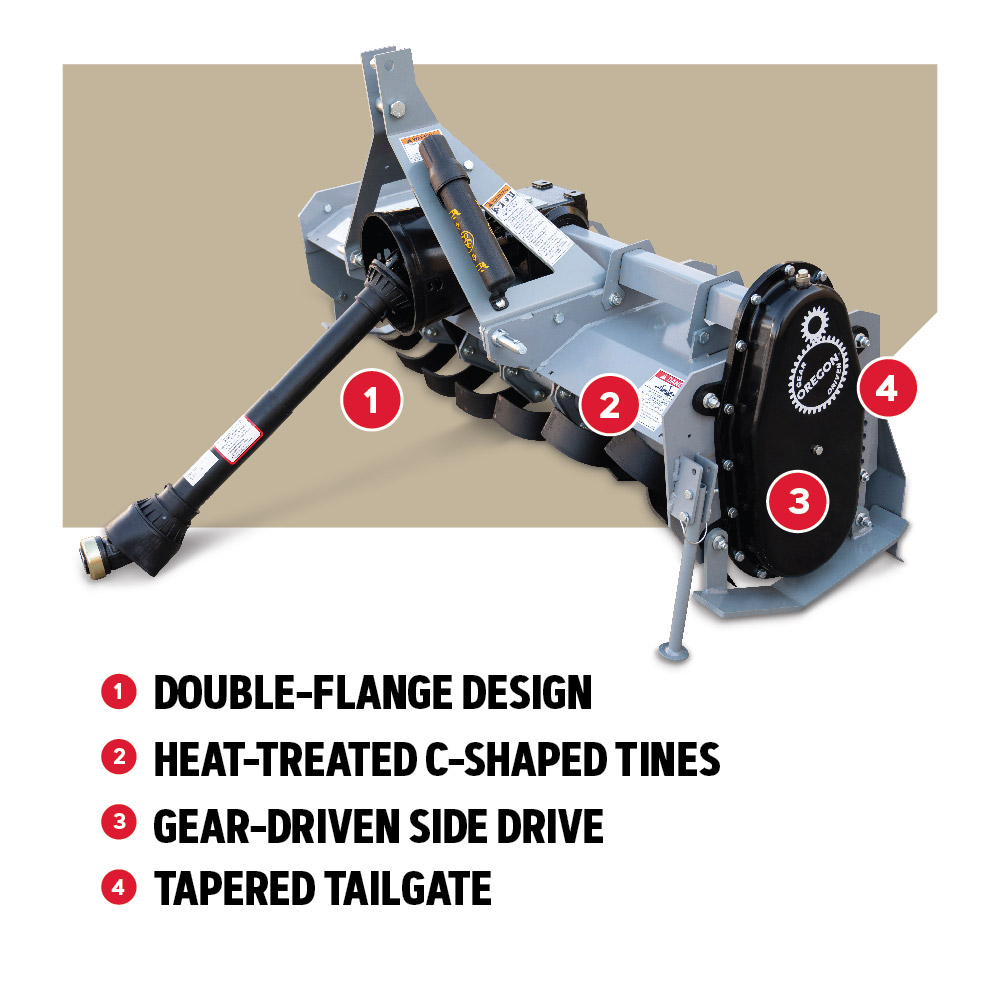

- Patented double-flange design secures and strengthens the blade support as well as providing long-lasting durability

- Fixed offset tiller covers tractor’s tire tracks and tapered tailgate smooths furrows for a finished seedbed, ready for planting

- Heat-treated, C-shaped tines reach deeply into the soil

- 4-blade per flange design uses less horsepower and can navigate through rocks and roots without plugging (compared to 6-blade). Ideal for wooded areas or heavily rooted, rocky areas.

- Easily adjust working depth with the skid shoes

- Gear-driven side drive is long-lasting and requires less maintenance than chain-driven units

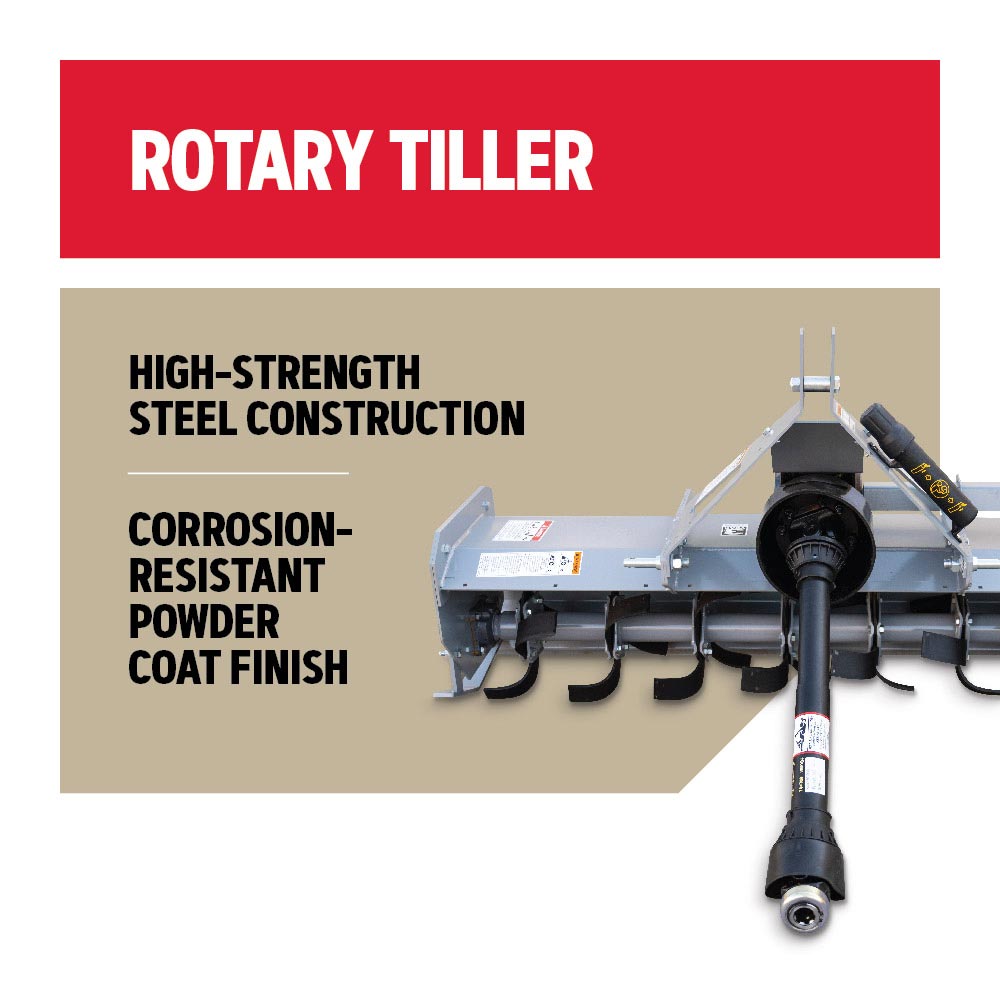

- High-strength steel construction

- Corrosion-resistant powder coat finish

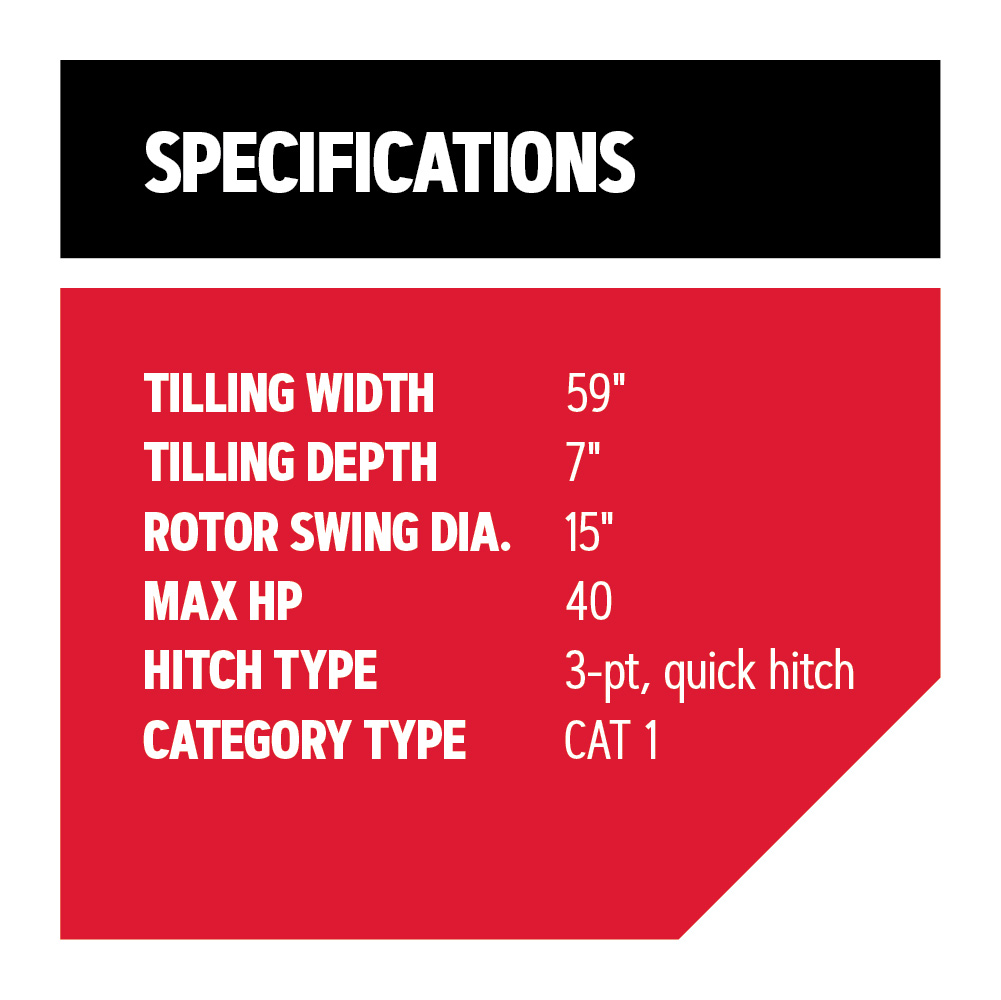

- Built for tractors with 18-40 HP

- 3-point category 1 connection or category 1 quick hitch compatible

- Made in the U.S.A. with U.S. and imported parts

- 3-Year Gearbox Warranty; 1-Year Tiller Warranty

Dimensions

- 7" Tilling Depth

- 59" Tilling Width

- 15" Rotor Swing Diameter

|

Patented double-flange design |

|

Fixed offset tiller |

|

Heat-treated, C-shaped tines |

|

4-blade per flange design |

|

Easy-adjust skid shoes |

|

Gear-driven side drive |

|

High-strength steel construction |

|

Corrosion-resistant powder coat finish |

|

3-point category 1 connection |

Frequently asked questions

Q: Do my gearboxes come from the factory filled with oil?

A: No. Be sure to pick up SAE-80W-90 oil before leaving the store.

Q: How do I fill the gearbox with oil?

A: Fill both gearboxes with SAE 80W or 90W gear lube until it runs out the side level plug. Use a 5/16" Allen wrench to remove the fill plug.

Q: What assembly is required?

A: The Rotary Tiller is shipped partially assembled. Assembly will be easier if components are aligned and loosely assembled before tightening hardware.

Q: Can I begin tilling at max tilling depth?

A: No. Tillage depth is dependent on ground hardness, tractor speed, skid shoe setting, and tractor hitch adjustment. Multiple passes may be necessary to achieve desired tillage depth.

Q: How do I adjust my tilling depth?

A: Loosen the ½" cap screws that act as the front pivots to the skid shoes. Remove the ½" cap screws that hold the rear of the skid shoes to the tiller frame. Adjust the skid shoe to the desired tilling depth. Reinstall the cap screws in the rear of the skid shoe and tighten all cap screws.

A: No. Be sure to pick up SAE-80W-90 oil before leaving the store.

Q: How do I fill the gearbox with oil?

A: Fill both gearboxes with SAE 80W or 90W gear lube until it runs out the side level plug. Use a 5/16" Allen wrench to remove the fill plug.

Q: What assembly is required?

A: The Rotary Tiller is shipped partially assembled. Assembly will be easier if components are aligned and loosely assembled before tightening hardware.

Q: Can I begin tilling at max tilling depth?

A: No. Tillage depth is dependent on ground hardness, tractor speed, skid shoe setting, and tractor hitch adjustment. Multiple passes may be necessary to achieve desired tillage depth.

Q: How do I adjust my tilling depth?

A: Loosen the ½" cap screws that act as the front pivots to the skid shoes. Remove the ½" cap screws that hold the rear of the skid shoes to the tiller frame. Adjust the skid shoe to the desired tilling depth. Reinstall the cap screws in the rear of the skid shoe and tighten all cap screws.

Q: What maintenance is required on my Rotary Tiller?

A: Some service and maintenance work must be done by a qualified dealership; special skills, tools, and safety procedures may be required. Consult your operator’s manual for details.

Q: Why do I have to adjust my driveline length?

A: If the distance is too large, the driveline will be too short for proper engagement. If the distance is too small, the driveline may bottom out in operation and damage the tiller or tractor.

Q: How do I adjust my tailgate?

A: Lock chain in place using lug on the rear of the tiller. The lower the tailgate is adjusted, the finer the tilth.

Q: How do I level my tiller?

A: Raise the tiller off the ground. Level tiller side to side. Check by measuring from the forward skid shoe pivot to the ground on each side. Adjust, using tractor 3-point arm leveling device.

A: Some service and maintenance work must be done by a qualified dealership; special skills, tools, and safety procedures may be required. Consult your operator’s manual for details.

Q: Why do I have to adjust my driveline length?

A: If the distance is too large, the driveline will be too short for proper engagement. If the distance is too small, the driveline may bottom out in operation and damage the tiller or tractor.

Q: How do I adjust my tailgate?

A: Lock chain in place using lug on the rear of the tiller. The lower the tailgate is adjusted, the finer the tilth.

Q: How do I level my tiller?

A: Raise the tiller off the ground. Level tiller side to side. Check by measuring from the forward skid shoe pivot to the ground on each side. Adjust, using tractor 3-point arm leveling device.